In today’s fast-moving world, where convenience drives everything and time feels like it’s always slipping through our fingers, we’re seeing the packaging industry face some serious demands. Whether it’s the bread bag we toss into our cart or the diaper pouch we grab for a quick change, we all rely on packaging that’s dependable and well-crafted. That’s where high-speed wicket bag machines come in—smart, game-changing tools that are helping us meet these needs head-on.

It feels like our shopping habits have completely turned upside down lately. With online orders stacking up and our on-the-go lifestyles becoming the norm, we’ve noticed that people expect their products to arrive safely, be easy to open, and show some care for the environment. We’ve come across reports saying the global packaging market is expected to grow at a steady CAGR of 4.8% in terms of value during 2020-2028, driven by huge demand in food, personal care, and industrial goods. Everyday items like bread bags, sanitary napkin pouches, and toilet paper roll bags—things we often overlook—are now needed in massive quantities, but without cutting corners on quality and our high-speed wicket bag making machines come in as the behind-the-scenes heroes.

Our wicketer side seal machine, can produce 300 bags per minute, which has been a game-changer for us in helping businesses keep supermarket shelves stocked or meet those last-minute online orders. We can just imagine a bakery racing to keep up with a sudden crowd or a diaper company preparing for a busy season—these machines help us keep everything running smoothly, no matter the pressure.

Speed is fantastic, but what really grabs our attention is the precision these machines offer. We know consumers today want packaging that works seamlessly with automated systems, keeping products fresh and secure. Our machine uses a clever system of take-up arms to stack bags onto needles, feeding them directly into filling machines. It might sound like a small thing, but it cuts down on mistakes and ensures every bag meets the high standards we know are crucial, especially in food and hygiene industries where there’s no room for error.

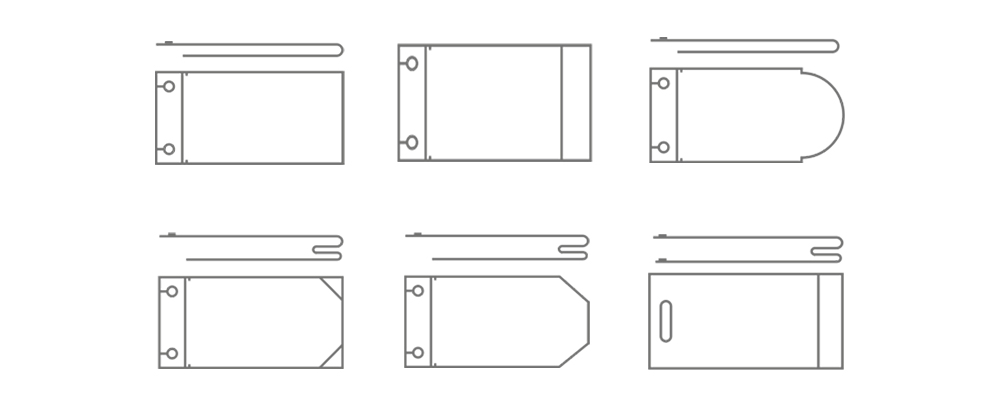

That’s something we’re really proud of. Our machines can handle materials like HDPE or LDPE and even add wicket punches with the right attachments. Whether we’re making a bread bag with a unique bottom shape or a sanitary napkin pouch with a clean side seal, we love that we can switch things up to keep manufacturers ready for whatever comes their way. With 2025 bringing a surge in personalized packaging for online shoppers, we’re finding that kind of adaptability more valuable than ever.

Sustainability is something we can’t stop thinking about these days. We’ve seen studies showing that around 85% of people worldwide are willing to change their buying habits to help the planet, and we feel that push too. Our high-speed wicket bag making machines are stepping up by making production more efficient—using less material and wasting less energy. We’ve worked hard to balance speed with thoughtful design, keeping things as eco-friendly as possible without slowing down.

What gets us really excited is that our machines can work with greener materials, like biodegradable or recyclable options, which are becoming non-negotiable as consumers demand better choices. We dream of a day when every bread bag or diaper pouch we help produce breaks down naturally, yet still comes off the line at top speed—that’s the future we’re working toward, and it feels like the perfect fit for what people care about in 2025.

In manufacturing, we know time is everything, and a delay can cost a lot. Our high-speed wicket bag making machines are built to handle the rush of today’s supply chains, where every second matters. We often say our plastic bag making machine is “extremely fast,” and we’ve seen firsthand why it’s become a go-to for high-pressure situations. With e-commerce packaging expected to claim a big chunk USD 124.9 billion by 2029, growing at 10.0% CAGR from 2024 to 2029, we know businesses can’t afford to fall behind—and we’re here to help them stay in the game.

As we move through 2025, we’re convinced that bag making machines will only become more essential. With people asking for faster deliveries, greener options, and packaging that’s made just for them, we feel ready to lead the way. Our solutions, like the wicketer side seal machine, show how technology can rise to the moment, blending speed, precision, and sustainability into something truly special.

In a year where every second counts and every decision matters, we’re proud to see high-speed wicket bag making machines quietly reshaping the way we package the world. For businesses aiming to stay ahead and consumers looking for convenience with a conscience, we believe these machines are the heroes we all need right now.